Jiajun board partition wall ceiling system

About Jiaheng

Guangzhou Jiaheng Board Industry Co., Ltd., referred to as "Jiaheng Board Industry", since 2006, adheres to the concept of "survive by quality, develop by reputation", and provides global consumers with green, healthy, natural and environmentally friendly products with superior performance. Green building materials, advocating love for the living space of human beings.

Jiaheng's products are mainly calcium silicate boards and fiber cement boards, which are widely used in lightweight walls, ceilings and exterior walls, indoor functional walls, and mezzanine floors of homes, offices, hotels, hospitals, factories, public places and other buildings. , firewall, etc. The product has the characteristics of light weight and high strength, waterproof and moisture proof, fire resistance and heat insulation, simple construction, high stability, sound insulation and sound absorption, environmental protection and pollution-free.

The company is located in Huadu District, Guangzhou City, close to Guangzhou New Baiyun International Airport. It is a new type of sheet metal production enterprise integrating R&D, production and sales. There are 4 most advanced sheet-making process production lines in the world, with an annual production capacity of 2000 With an area of 10,000 square meters, it is one of the largest new plate manufacturers in South China.

Production line equipment

International Quality Global Certification

Jiaheng Jiajun Board

Low density anti cr acking

A new ultra low density fiber reinforced calcium silicate board

Product Standards

JC/T412 1-2006 Fiber reinforced calcium silicate board Part 1: Non-Asbestos calcium silicate board

Al grade material /Real material /Green environmental protection

Product ingredients

This A class green decorating material is autoclaved from several siliceous, calcium, fiber raw material, which is environmental protection, safety, stable, and high level architectural decoration and finishing material with ultralow density enhanee calcium silicate board.

Green material Green construction Green energy saving

Jiajun board ultra-light anti-cracking surface material

Ultra-low density Jiajun board is a representative product developed by Jiaheng Board Industry, which is specially designed to solve the cracking of wall and ceiling. As an A2 grade partition wall/ceiling substrate with superior performance, the material details are tobermullite molecular structure, with excellent stability and excellent crack resistance, which can replace wooden plywood and gypsum board, traditional fiber cement board Class decoration substrate, the scope of application is not limited.

tobermorite-like molecule

Using a variety of silicon and calcium as the main materials, using silver pressing and pressing technology, through steam curing, surface polishing and other treatments, artificial hydrated silicic acid with tobermorite (C5S6H5) crystal structure is formed. calcium minerals.

Basic Features

I. A-level environmental protection

Use Class A non-combustible inorganic materials. No radiation, no deformation, stable physical and chemical properties.

Second, acid and alkali corrosion resistance

Portland cement, quartz sand and selected minerals and other major inorganic raw materials. After high temperature autoclave curing, the physical and chemical properties are excellent. It has been proved by physical and chemical experiments that it can effectively resist acid and alkali corrosion without mildew.

Third, light weight and high strength

Light weight and high strength. While reducing the structural load of the building, it also has excellent mechanical properties.

Four. Waterproof and moistureproof

The lightweight surface itself has Water permeability, its unique tobermorite crystal molecular structure can regulate indoor relative humidity. Even in the southern sky season, it can be done without water splitting.

5. Fire and non-flammable

The incombustibility reaches the national A-level standard . The wall system has good fire resistance, which can limit the fire and smoke and gas in the fire area, and does not emit toxic gas, which is an extra guarantee for your safety.

Six. sound insulation

through multiple material transitions of different densities , It has good sound insulation effect and sound wave consumption function, enhances sound insulation and restores quietness.

Product performance

|

items |

Ultra Low Density Jiajun Board |

|

implement standard |

JCC564丄-2008"fiber-reinforced calcium silicate board part 1: Asbestos-free calcium silicate board" |

|

Product Composition |

High-purity quartz sand+mica+perlite and other minerals Filler + vegetable fiber + appropriate amount of low alkali cement |

|

Model size |

2440xl220x6~10mms 12mm, 15mm |

|

densityg/cm3 |

Ultra Low Density:0.82WDW0.95 ; low density:0.95< ;DWl.l |

|

Swelling% |

W0.25 |

|

Flexural StrengthMpa |

>6,Aspect RatioM58% |

|

thermal conductivityW/(m . k) |

W0.2 |

|

Heat Shrinkage% |

W0.50 |

|

Environmental evaluation |

100%No asbestos, no harmful substances |

|

radioactive |

AClass materials, production, sales and use are not limited. compoundGB6566《Building Material Radionuclide Limits》 |

|

Incombustibility |

A1Class non-combustibility, in line withGB8624 |

green evaluation

-

Green material:

Use Class A non-combustible materials, and the combustion index, heat dissipation index, flame index, and smoke index are all 0; Class A decoration materials have no radiation, and their production, sales and use are not limited. The tobermorite crystal structure is synthesized by mixing a variety of siliceous and calcareous materials through high temperature and high pressure reaction, and the performance is extremely stable.

-

green technology:

Effectively reduce water, electricity, consumables, etc., reduce construction waste and dust pollution, shorten the construction period, greatly reduce the energy consumption of construction activities and construction use, and reduce the sub-item civilized construction rate by 50%;

-

Green construction:

Greatly improve labor efficiency, reduce the number of people working on site, save labor costs, achieve the goal of four sections and one environmental protection (energy saving, land saving, water saving, material saving and environmental protection), and reduce dust, noise, sewage, harmful gases and construction waste;

-

Assembly evaluation:

In line with the process requirements of the "Evaluation Standard for Prefabricated Buildings", standardization of design, industrialization of components, modular installation, dry operation, etc., the construction speed is fast, and it is less restricted by climatic conditions, saving labor and improving building quality. At the same time, it complies with the relevant index requirements of the "Green Building Evaluation Standard".

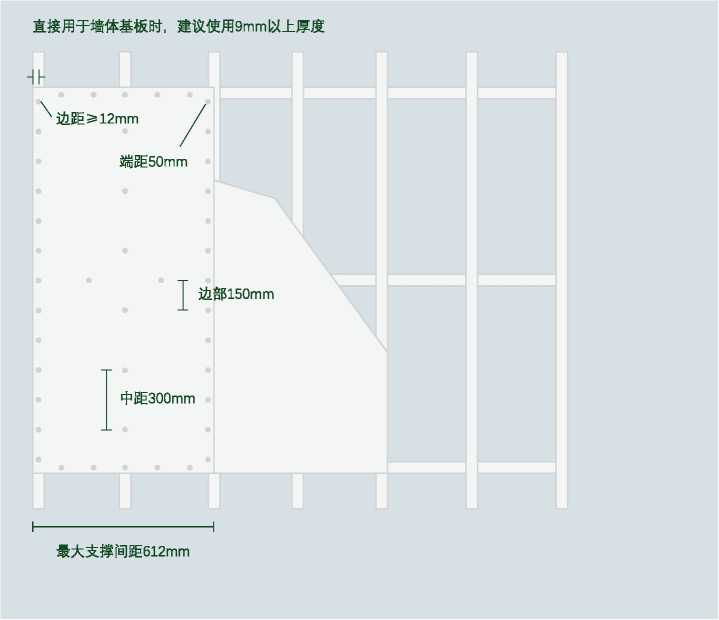

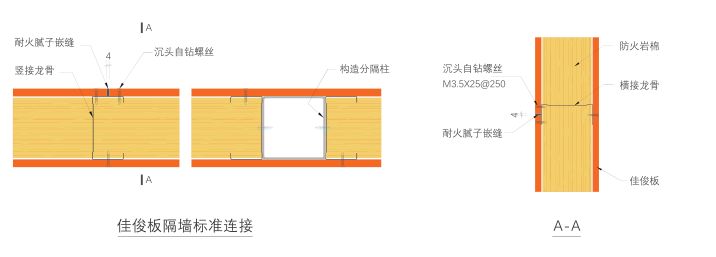

Wall use points

1. Light steel keel: The light steel keel used in the partition wall should comply with GB/T 11981-2008 "Light Steel Keel for Construction", with a thickness of 0.6 ~ 1.2mm; the amount of double-sided galvanizing is 100g/m2.

2. Hardware accessories and auxiliary materials: The accessories of the partition wall are mainly expansion bolts, self-drilling screws, core-pulling steel nails, sealing materials, etc.

3. The keel and the building structure should be firmly connected. The connection between the frame of the keel and the building structure is fixed by expansion bolts, the spacing should not be greater than 800mm, and the distance between the bolt and the end of the wall should not be greater than 150mm. The connection between the vertical keel and the horizontal keel shall be fixed with core-pulling nails with a diameter of 4 mm and a length of 8 mm.

4. The plate is fixed on the keel with countersunk head self-tapping screws. The specifications of self-drilling screws are generally 3.5~4.2mm in diameter and 20~35mm in length. A gap of 3~4mm is reserved between the boards, which is filled with caulking bonding materials such as building gypsum putty, and glass fiber mesh cloth is used for anti-cracking treatment.

5. For walls with high sound insulation requirements, thicker panels or double-layer panels, or double-row keel structures can be selected, and the sealing should be strengthened, and sound-absorbing materials should be filled in the keel cavity.

6. When the continuous length of the light steel keel partition exceeds 6m, a structural column or additional keel should be installed.

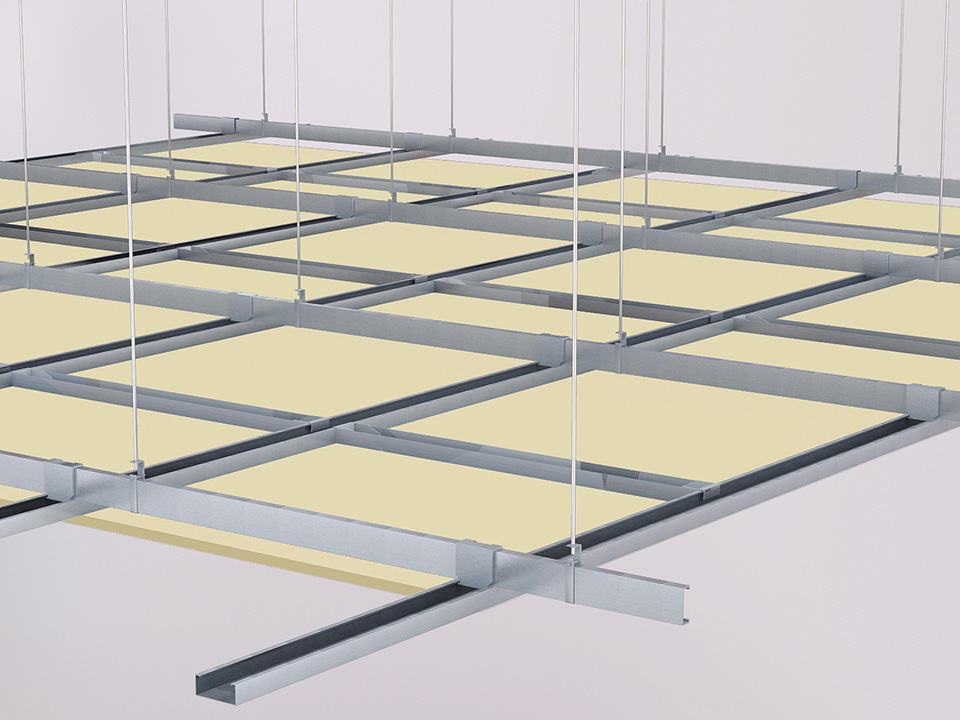

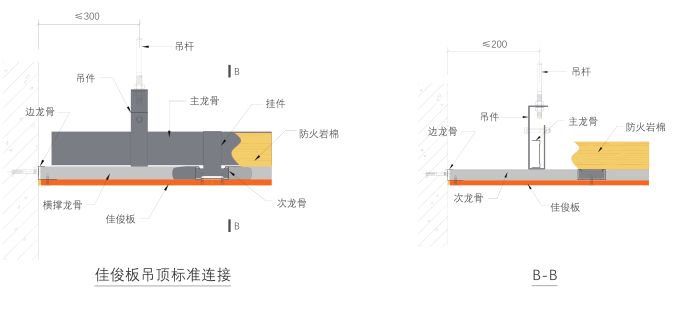

Requirements for the use of suspended ceilings

1. The distance between the main keel and the boom should generally be less than 1500mm, and when it is greater than 2500mm, anti-support should be set up. The distance between the boom and the boom should not be greater than 1200mm. The distance between the boom and the end of the main keel should not be greater than 300mm. When it is greater than 300mm, the boom should be added. The boom should be straight and should not be bent or skewed.

2. When the keel must be lengthened with an extension piece, in order to avoid affecting the overall rigidity of the keel, the joints should be arranged in dislocation.

3. When the ceiling has high sound insulation and fire protection requirements, fillers such as rock wool and glass wool can be built in.

4. When the length of the ceiling is ^ 12m or when it encounters expansion joints in the building structure, expansion joints must be set. The width of the expansion joint is generally 8~10mm.

5. Heavy lamps, fans and other heavy equipment are strictly prohibited to be installed on the ceiling keel, and should be hoisted with additional hooks.

6. When the master is overhauling, the personnel must stand on the horse road to work, and it is strictly forbidden to directly step on the main and auxiliary bones or plates of the ceiling. When operating, try to avoid shaking the entire ceiling frame sideways, so as to avoid deformation or cracking of the board.

7. When the ceiling adopts double-layer plates, the two-layer plates should be installed with staggered joints.

8. The distance between the self-tapping screw and the edge or end of the plate should not be less than 10mm, nor should it be greater than 30mm, because it is limited by the section of the keel. The spacing of the screws in the middle of the board shall not be greater than 200mm. When fixing, the nail head is required to be embedded in the plate by about 0.5~1mm.

9. After the board is installed, stabilize the board as much as possible, and then carry out joints and surface treatment to avoid dry shrinkage and cracking due to different use environments.

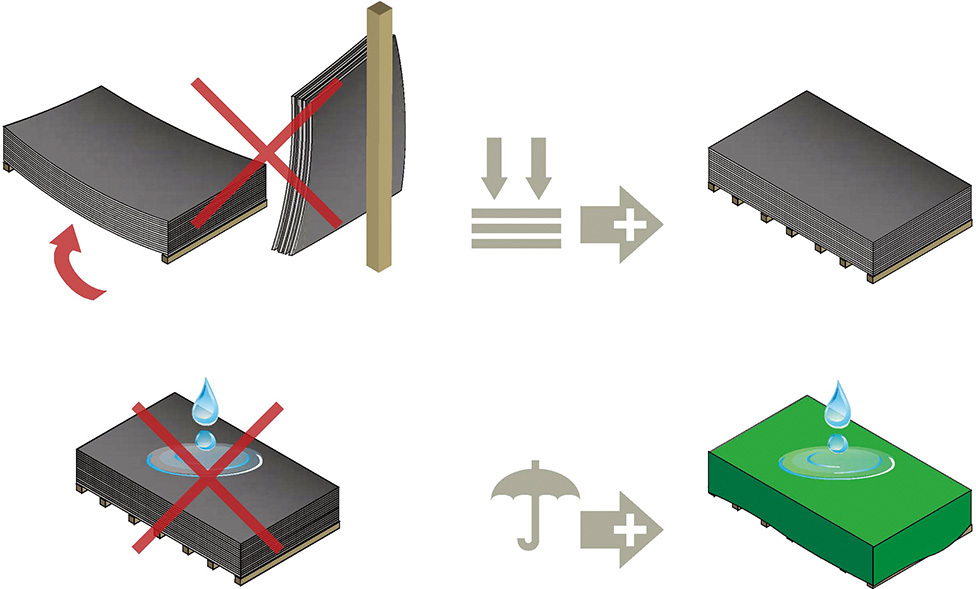

Storage and handling precautions

a. The board should be placed horizontally on the wooden frame or bracket

b. It is forbidden to place the plate leaning against the fixed position

c. When in the open air, take precautions against rain and snow

d. Avoid direct contact of the sheet with water or liquids at all times

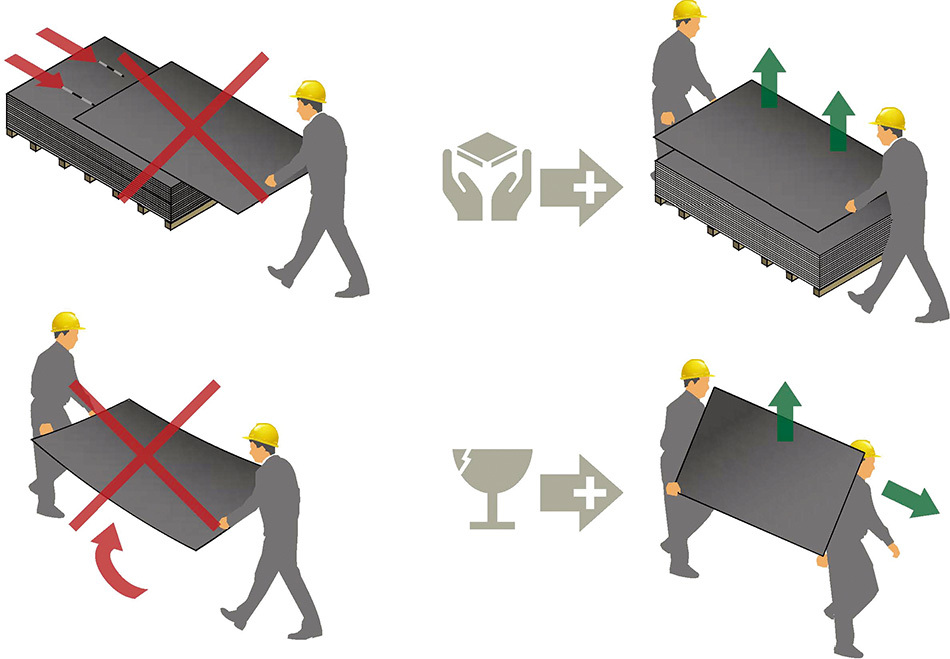

e•When transporting, it should be lifted from both ends of the plate, and the inclined angle should be maintained when moving.

f. Prohibition of single-person handling operations, and prohibition of deformation and handling of plates

Selected Cases

Tianhe City Department Store

Tianhe City store ultra-low density Jiajun board

Tianhe City Department Store

Beijing Road Store Lightweight Partition Wall Ceiling

Yuexiu Fortune Plaza

Ultra-low density Jiajun board at Xiwan Road

Guangzhou Zhongda International Textile Co., Ltd.

Xingang West Road Ultra Low Density Jiajun Board

Shunde Xinbao Plaza

Jiajun board, part of Tianhong Road shopping mall

Hualin International Jade City

Kangwang Road Jiajun board ceiling

Related news

2021-09-15

2021-09-15

Hotline: 008613318898449

Address: No.23,Tanbu Industry Zone,Tanbu Town,Huadu District,Guangzhou,Guangdong,China.

Email: sanly@jiahengboard.com

We will give you feedback in time

Guangzhou Jiaheng Board Industry Co.,Ltd.

Mobile/Wechat: 008613318898449

Tel:020-86843698

E-mail:sanly@jiahengboard.com

Address: No.23,Tanbu Industry Zone,Tanbu Town,Huadu District,Guangzhou,Guangdong,China.

Guangzhou Jiaheng Board Industry Co.,Ltd. seo

粤ICP备14070170号 Power By:www.300.cn

[ WeChat ]

[ Mobile ]