These qualities of fiber cement boards are deeply loved by designers!

Fiber Cement Board

Fiber cement board refers to a board made of cement as the basic material and adhesive, with mineral fiber cement and other fibers as the reinforcing material, through pulping, molding, curing and other processes. Fiber cement board substrates are widely used in various domestic power plants, chemical enterprises, large shopping malls, hotels, guesthouses, theaters and other public places indoors as important fire-retardant materials. At the same time, many fiber cement boards with surface decoration effects are widely used in indoor and outdoor wall decoration of buildings, which are very popular among designers!

Jiaheng board industry has two series of fiber cement board products: Jiaheng Jialai board and Jiaheng Jiabao board. Jiaheng products have obtained the national authoritative certification "China Environmental Labeling Product Certification" (referred to as green environmental protection), which is the national advocate of energy saving and environmental protection. Environmentally friendly building materials.

Jiaheng Jialai board, fiber cement board decorative surface material, uses natural raw materials, including Portland cement, selected quartz sand, plant fibers, natural mineral pigments and other real materials, after high temperature autoclave curing.

Jiaheng Jiabao board, fiber cement board floor board, adopts pure Portland cement, selected quartz sand, plant fiber, and selected mineral filler. Among them, cement is the main component, which acts as a hydraulic binder; the interaction between the fiber component and the cement matrix generates a stable matrix structure; after the mineral filler is ingested and cured by high temperature autoclave, tobermorite-like molecules are formed. The structure and physical properties are extremely stable.

Jiaheng products, 100% asbestos-free, no pollution, no radiation, no doubt, this is a real green material

Performance

Fiber cement board sheets can be used as indoor ceiling materials and can be perforated as sound-absorbing ceilings. Conventional slabs are also widely used in walls and/or decorative surfaces, and thick slabs can be used as LOFT steel structure floor slabs, duplex slabs, exterior wall hanging boards, clear water boards, etc. Its performance has the following characteristics:

1. Fireproof insulation: non-combustible class A, the board will not burn when a fire occurs, and no toxic smoke will be produced; low conductivity, it is an ideal insulating material.

2. Waterproof and moisture-proof: In semi-open air and high-humidity environments, it can still maintain stable performance and is not easy to sag or deform.

3. Thermal and sound insulation: low thermal conductivity, good thermal insulation performance, and good sound insulation.

4. Light weight and high strength: The plate pressurized by a 5,000-ton flat hydraulic press not only has high strength, but also is not easily deformed and warped; it is light in weight and suitable for use in roof partitions and suspended ceilings.

5. Simple construction: dry operation method, the installation and construction of keel and plate are simple and fast. Deep-processed products also have the characteristics of easy construction.

6. Long service life: strong weather resistance, will not be damaged by moisture or insects, etc., and the strength and hardness will increase with time, and have the same life as the building.

Technic | Category

1. According to fiber: Cement fiber board spacing functional fireproof and waterproof partition lining board. Fiber can be divided into asbestos and non-asbestos board. At present, paper fiber is mainly used in China.

(Low density cement fiberboard↑)

2. According to density: low density 0.9-1.2g/cm3, medium density 1.2-1.5g/cm3, high density 1.5-2.0g/cm3. Low density is generally used for ordinary building ceiling partitions and other parts, medium density is generally used for mid-range building partition walls and ceilings, and high density is generally used for high-end building steel structure exterior walls, steel structure floors, etc. Construction industry standards are divided into two categories.

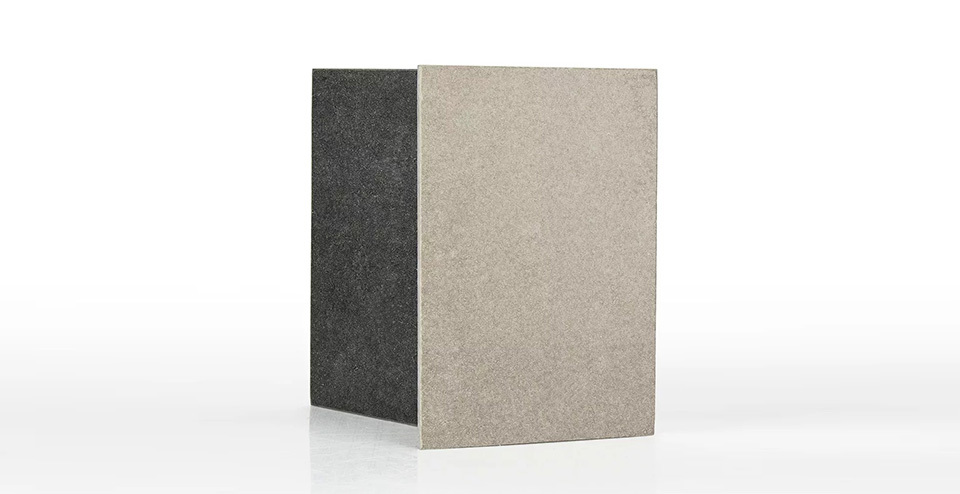

(medium density cement fiberboard↑)

(medium density cement fiberboard↑)

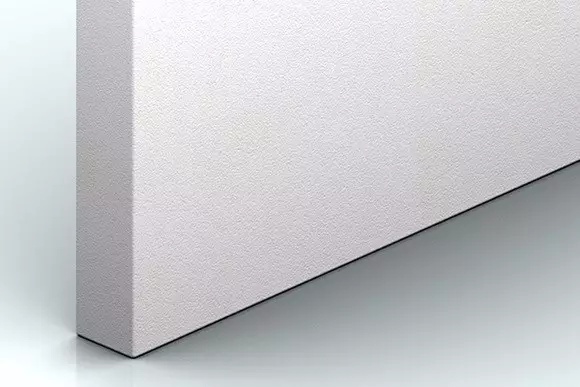

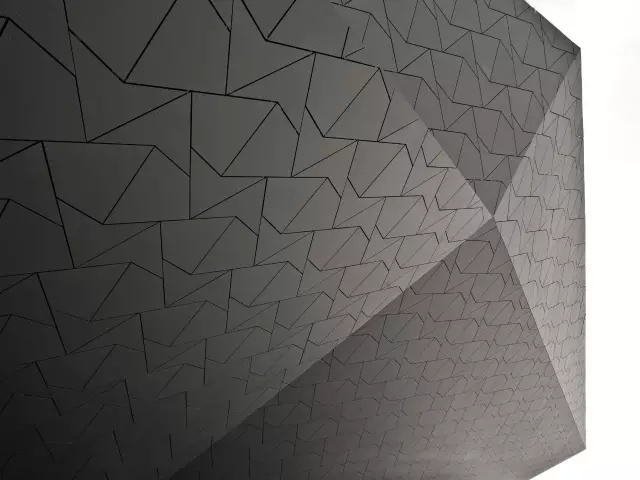

(High-strength pressure plate ↑)

(High-strength pressure plate ↑)

3. According to the pressure: whether there is a pressure plate and a pressure plate. Medium and low density fiber cement boards are all pressure-free boards, and high-density fiber cement boards are pressure boards. Pressure plates, also known as fiber cement pressure plates, require special presses to produce, and companies without presses cannot do it.

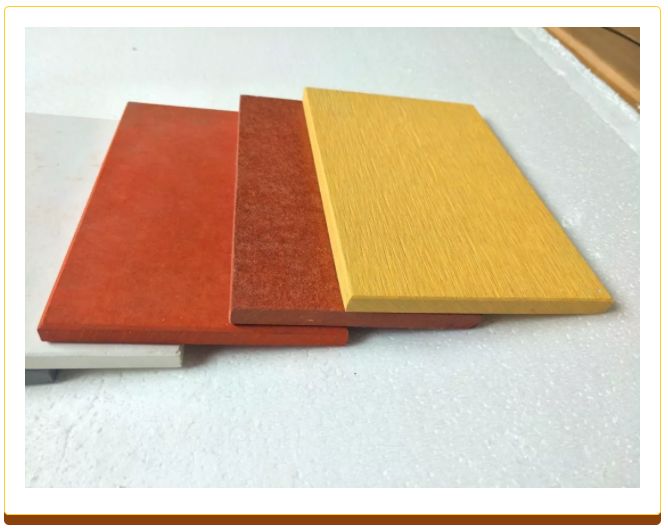

(multi-color cement fiberboard ↑)

4. According to thickness: 1) Ultra-thin plate, 2.5-3.5mm; 2) Regular plate, 4-12mm; 3) Thick plate, 13-30mm; 4) Ultra-thick plate, 31-100mm.

InnovaToren Netherlands↓

Erl Tirol - Festival hall , Austria ↓

Moselle Town Square ↓

Sino-French Center, Tongji University, Shanghai ↓

Southern University of Science and Technology Library ↓

Related news

2021-09-15

2021-09-15

2021-09-15

Hotline: 008613318898449

Address: No.23,Tanbu Industry Zone,Tanbu Town,Huadu District,Guangzhou,Guangdong,China.

Email: sanly@jiahengboard.com

We will give you feedback in time

Guangzhou Jiaheng Board Industry Co.,Ltd.

Mobile/Wechat: 008613318898449

Tel:020-86843698

E-mail:sanly@jiahengboard.com

Address: No.23,Tanbu Industry Zone,Tanbu Town,Huadu District,Guangzhou,Guangdong,China.

Guangzhou Jiaheng Board Industry Co.,Ltd. seo

粤ICP备14070170号 Power By:www.300.cn

[ WeChat ]

[ Mobile ]