Jialelai wood grain board series

Product Series

Certification authority

Jialelai wood grain board

Jialelai wood grain board is a kind of exterior wall decoration material with real natural wood grain relief effect and various imitation stone paint or exterior wall paint sprayed on the surface. It is composed of low-alkali cement, high-purity quartz sand, mica perlite and other mineral fillers, plant fibers, and is processed by high-temperature autoclave curing and special processing. With outstanding environmental protection features and elegant appearance, it can replace stone, cultural stone and aluminum-plastic panel. It is the best choice for decoration and renovation of exterior and interior walls of buildings today and in the future.

Application field

Exterior wall decoration or roof renovation, eaves bottom decoration, indoor ceiling decoration, floor and wall decoration, wall skirt decoration, indoor partial decoration, decoration fireproof and waterproof lining skirting and top corner line, inner and outer corner cornice edge sealing , door sets, window sets, decks, cushion railings around pier pools, fences, etc.

Superior performance

Variety of wood grain appearances and unlimited color options

The physical properties are super strong, and the surface relief is completely formed under high pressure, which ensures the consistency of thickness and the authenticity and naturalness of texture in the butt joint of blocks and blocks and boards and boards. The surface can be painted at will for a variety of color and texture options. The board has a certain degree of bending, which can meet the needs of complex modeling, so that the lines can be perfectly integrated with the surrounding environment. Whether it is used locally or as a whole, it presents a fashionable and elegant atmosphere, making the building more aesthetic and friendly.

Outstanding features

Good overall uniformity, fireproof, waterproof, moth-proof, excellent material, durable, wear-resistant, stable and not deformed, warped, rotten and delaminated. Whether it is wind, frost, snow, rain, scorching sun or acid and alkali erosion, it can easily deal with it. The quality has remained unchanged for decades. It has impeccable performance in solving the renovation and decoration of exterior and interior walls.

Eco-friendly

Jialelai wood grain board is composed of a variety of siliceous and calcareous inorganic substances and log pulp fibers. It is 100% free of asbestos and non-radioactive. The carefully selected materials are under the strictest production standards, so that each wood grain board meets the highest environmental standards.

Super processing performance

Like wood, Jialelai wood grain board can be easily cut, drilled, sawed and shaped with hand and power tools, saving time and labor. Wood grain boards can be lapped horizontally, vertically or obliquely, presenting a varied and attractive façade effect.

confidence guarantee

Products and building systems are developed and manufactured in strict accordance with ISO9001 and ISO14001 quality standards. Matsumoto technicians have years of professionalism, strict training and rich experience, which can help customers maximize benefits and give customers enough confidence in quality assurance.

No worries about post-maintenance

Jialelai wood grain board products and systems are suitable for various building structures. After construction, there is basically no need for care and maintenance, which reduces building energy consumption and secondary energy use, and brings long-term energy-saving benefits to buildings. It is a short-term economic benefit behavior. One of the best architectural means incomparable.

Due to differences in coating climate, basic conditions and construction methods, the color of the surface of the sample and the allowable difference in supply. For special colors, please contact us.

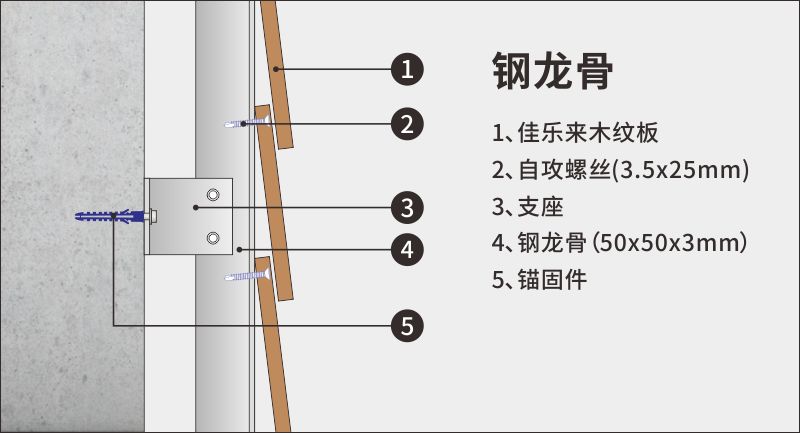

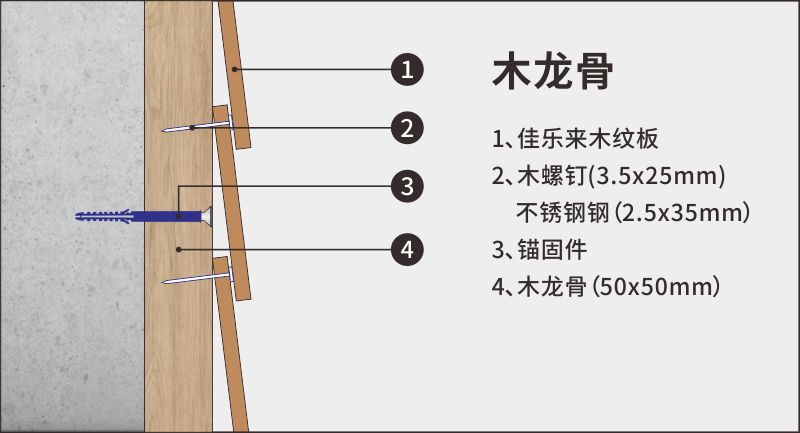

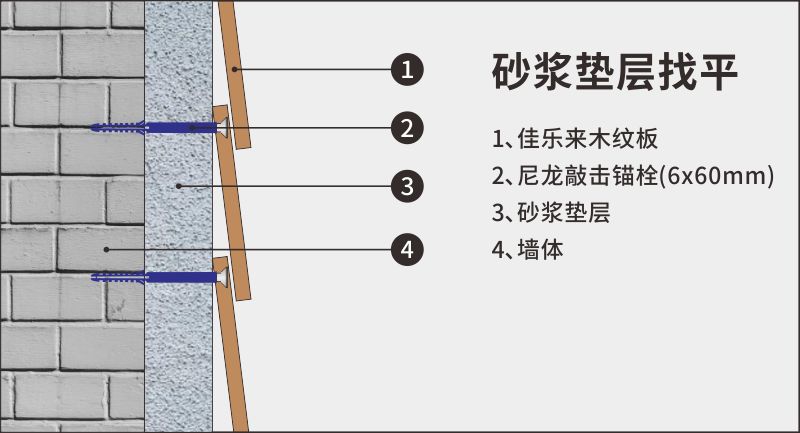

In general, steel keel or wood keel structure can be used to fix Jialelai wood grain board.

Jialelai wood grain board can be fixed on the steel keel frame with self-tapping screws, or fixed on the wood keel frame with steel nails. The skeleton is fixed to the structural wall by means of anchors. The section width of the cladding keels shall not be less than 50mm, the center distance between the keels shall not be greater than 600mm, and each plate shall span at least three keels. If the plate is supported by only two keels, the distance between the two keels shall not be greater than 400mm. If the wall itself is very flat, the board can be directly fixed on the wall, such as a very flat brick wall, the wall after leveling with mortar.

Skeleton system

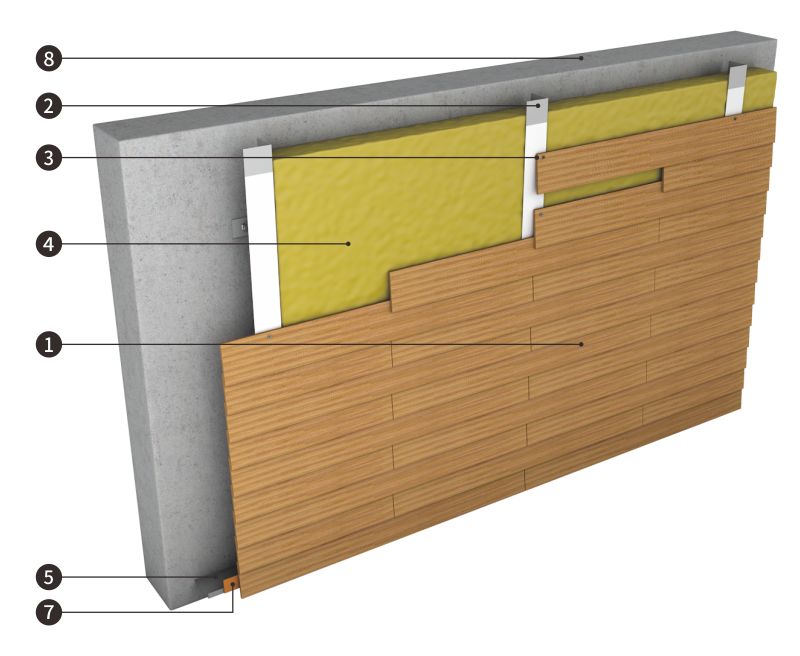

Many building exterior walls often need to consider thermal insulation and decorative functions. The use of wood grain board can easily achieve both thermal insulation and decorative functions. The wood grain board is constructed by light steel keel skeleton structure or wood keel skeleton structure or mortar sand cushion structure. In addition to other auxiliary materials, it can meet the needs of various external wall insulation and decoration, making the building look beautiful and fashionable, as long as it is new.

①Jialelai wood grain board ②keel skeleton

③Self-tapping screws ④Insulation material

⑤Screen ⑥Waterproof film

⑦Slatted ⑧Base Wall

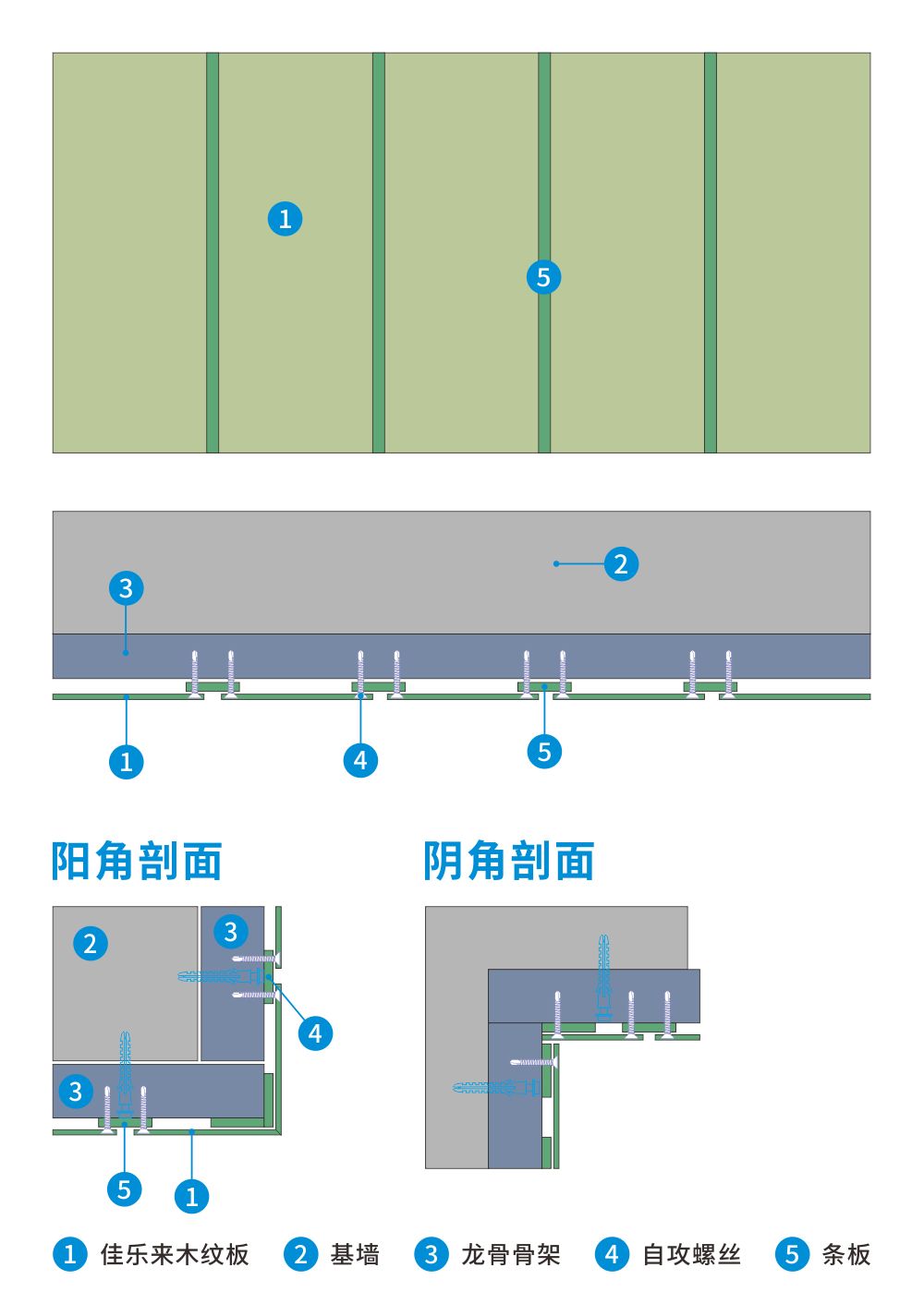

Facade arrangement

When the keel skeleton structure is adopted, the vertical keel shall be fixed on the base wall by means of angle code or wall clamp with expansion bolts, the fixed distance is ≤800mm, and the center distance of the vertical keel is ≤600mm. The wood grain board is fixed on the vertical keel with ¢3.5x25-40mm self-tapping screws. The installation of wood grain boards generally starts from the bottom of the building. In order to make the first board at the bottom have a certain inclination, it is necessary to use a slat with a width of 50mm and the same thickness as the board to cushion the board. In order to ensure the firmness and stability of the board, the vertical joints between the boards should be staggered from each other. The vertical overlap between the plates is 30-50mm.

If there is a connection between the board and the outside world, it needs to be enclosed and sealed with a screen to prevent small animals from entering. In addition, in order to prevent rainwater from entering the skeleton, it is necessary to add a layer of waterproof film behind the vertical joint of the two boards and stick to the back of the board.

When choosing wood keel, the wood keel needs to do the necessary anti-corrosion treatment. The wood grain board can be fixed on the wooden keel with iron nails or wood screws, and the seams between the boards are staggered. The frame and plate installation requirements are the same as the light steel keel frame structure.

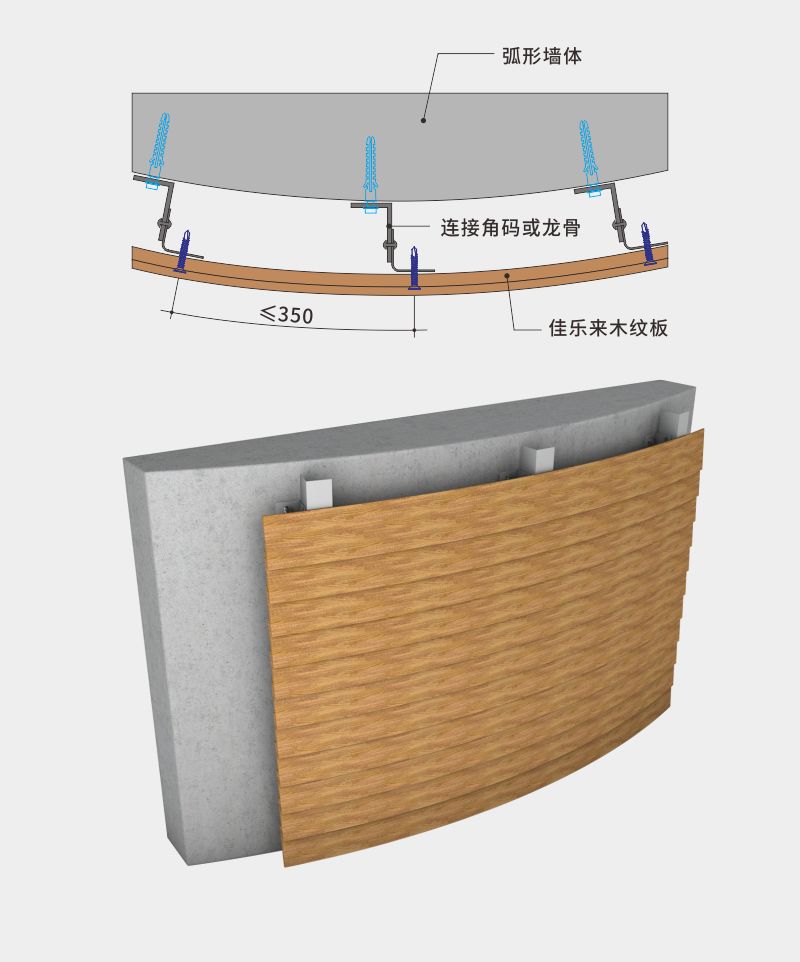

curved structure

Jialelai wood grain board can be bent under normal conditions.

7mm thick sheet bending radius: ≥1200mm;

9mm thick sheet bending radius: ≥1800mm;

12mm thick sheet bending radius: ≥3000mm.

The vertical keel center interval of the fixed plate is less than or equal to 350mm.

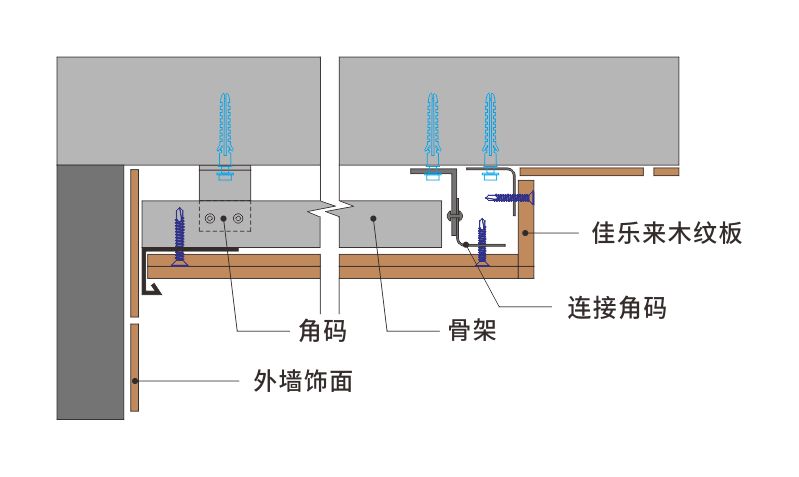

end construction

There are connected walls: There should be a certain gap between the board and the wall to facilitate the fixing of additional decorative parts.

Free end: Use plate to seal the edge, and can also use various corners to seal the edge. You can refer to the structure of the outside corner.

Indoor system

The outstanding performance of Jialelai wood grain board makes it also a surface material for interior decoration. It can be widely used in ceiling, wall or indoor partial decoration, and can also be used in places where fire, water and corrosion are required. Its surface can be treated with various colors, and can also be used in primary colors, which can easily meet the different design needs of users. The following configurations are available for indoor applications. There are many ways to apply the sheet, and the direction of the decorative seam can be vertical, horizontal or inclined. For the method and material selection of indoor and outdoor applications, please contact the personnel of our application technology department.

seam stitching

When it is necessary to carry out large-area ceiling, wall or local decoration indoors, the slotted splicing method of wood grain board can be used. The surface of the wood grain board and the board behind the joint are on different planes. When using, the board on the surface layer and the board at the joint can be processed into the same color, or the joint can be emphasized with a contrasting color.

Facade arrangement

Material consumption (unit area)

The following table shows the basic consumption budget of materials and accessories for the combination of wood grain board and light steel keel frame without opening, 10 meters long and 3 meters high, for reference only. The actual amount should be calculated in detail according to the specific project situation.

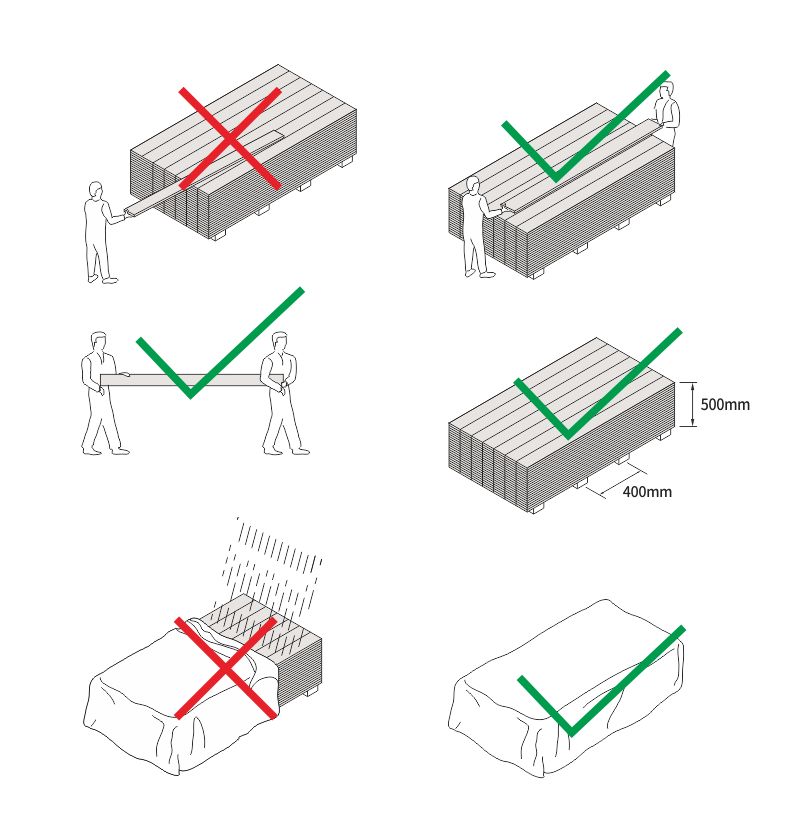

carry

Packed in bundles before leaving the factory. Each bale is carried by two people, and the short side of the board must remain vertical during the handling process, whether it is a bale or a single piece.

store

Although it can resist the harsh natural climate, it must be stored indoors. The board should be placed on a dry, flat and solid object, and it is strictly forbidden to place it directly on the ground. Each stack of sheets is covered with a waterproof membrane while ensuring that the sheets are open to the surrounding air. Wood grain boards should be stacked neatly according to different sizes and specifications, and should not be scattered upright or obliquely. The maximum height of each stack is 500mm.

cut

The cutting of Jialelai wood grain board is extremely simple, manual or electric cutting tools (such as cutting knives, woodworking saws or carbide saws) can be used. Sheets and cutting machines must remain stable during the cutting process to prevent irregular nicks on the edges of the sheet. Cut with the right side of the sheet facing up. A jigsaw can be used in some special shapes. In order to ensure the hygiene and environmental protection of the construction site, it is best to use an electric cutting machine with a vacuum cleaner device.

Install

The installation of Jialelai wood grain board generally starts from the bottom and gradually fixes it upwards. Before installing the first board, install a 100mm wide slat of the same thickness as the wood grain board. The lap thickness of the plates is generally 30-50mm. The screws for fixing the board should be 20mm away from the edge of the board. When fixing, the nail head needs to sink into the board surface.

Safety Construction Precautions

● Cutting wood grain boards in an open outdoor or well-ventilated environment;

● Use electric cutting equipment with vacuuming device;

● Cutting operators should wear masks;

●Use a vacuum cleaner to absorb or spray the remaining dust from sheet metal processing and then clean it up. The cleaned dust should be placed in a garbage bag to avoid dust flying;

●The remaining plate scraps can be treated as construction waste to avoid damage to the ecological environment;

●The installation process should be operated according to the engineering safety requirements.

Finishing

Jialelai wood grain board retains the original color of the board when it leaves the factory, and the surface does not have any decorative treatment. Users can decorate the board with exterior wall paint on the construction site. For specific decoration, please refer to the instructions of the paint manufacturer.

Featured Cases

Related news

2021-09-15

2021-09-15

2021-09-15

Hotline: 008613318898449

Address: No.23,Tanbu Industry Zone,Tanbu Town,Huadu District,Guangzhou,Guangdong,China.

Email: sanly@jiahengboard.com

We will give you feedback in time

Guangzhou Jiaheng Board Industry Co.,Ltd.

Mobile/Wechat: 008613318898449

Tel:020-86843698

E-mail:sanly@jiahengboard.com

Address: No.23,Tanbu Industry Zone,Tanbu Town,Huadu District,Guangzhou,Guangdong,China.

Guangzhou Jiaheng Board Industry Co.,Ltd. seo

粤ICP备14070170号 Power By:www.300.cn

[ WeChat ]

[ Mobile ]