Application of Fiber Cement Board in Steel Structure

Jiaheng fiber cement board is made of natural raw materials, including Portland cement, selected quartz sand, plant fibers, natural mineral pigments and other real materials, and is cured by high temperature autoclave. The cement and siliceous materials in the raw material of Jiaheng fiber cement board are subjected to autoclave reaction, which is not a cement board in the traditional sense. It inherits the advantages of waterproof and anti-corrosion of cement, and overcomes the shortcomings of ordinary cement products that are easy to dry and shrink; at the same time The board does not contain harmful substances such as asbestos. It is a new type of board with excellent performance, green health, natural environmental protection and wide application.

product advantages:

⑴Green environmental protection: 100% free of harmful substances such as asbestos, benzene and formaldehyde, and no toxic gas or radiation is generated during use. Green, safe and healthy!

(2) Fire and flame retardant: The board is a grade A1 non-combustible material, which will not burn. Even in a fire, it will not produce toxic smoke and no flame transmission. And low thermal conductivity, good thermal insulation performance!

⑶ Waterproof and moisture-proof: The sheet has stable performance, low wet expansion rate and dry shrinkage rate, and has good waterproof, moisture-proof and frost-proof performance even in the open air or humid areas.

⑷ Thermal insulation: The board uses high-grade cement and plant fiber structure, and the integrated board formed by compounding with polyurethane board has obvious advantages in thermal insulation performance and greatly reduces building energy consumption.

⑸Anti-corrosion and moth prevention: The materials are exquisite and the technology is advanced, which makes the board anti-aging, anti-weathering, good durability, not mildew and rot, and all kinds of insects and ants can do nothing to it.

⑹ Sound insulation and sound absorption: The board has good sound insulation performance, and can be combined with other sound absorption materials to form walls or barriers that meet various sound insulation requirements.

⑺Good earthquake resistance: Using this plate as a partition wall, the weight is only 1/15 of the brick wall of the same thickness (which can effectively reduce the construction cost), which is beneficial to the structure's earthquake resistance.

⑻ Lightweight and high-strength: The plate is light in weight, high in strength, and good in toughness. The thin plate can even be covered in a curved shape, which is easy to construct and handle, and is not easy to be damaged.

⑼Good weather resistance: The high-density board is densified by a 10,000-ton press, and the dry shrinkage and wet expansion performance and strength of the product are greatly improved. It has excellent weather resistance and long service life.

⑽Convenient construction: The plate is usually dry construction, which is quick and convenient, without plastering, and can be directly sprayed with paint; it is easy to drill, plan edges, saw and other secondary processing.

Product application range:

Green environmental protection, fire and flame retardant, waterproof and moisture-proof, anti-corrosion and moth-proof, sound insulation and sound absorption, light weight and high strength, convenient construction and good weather resistance, etc., make fiber cement board and its post-processing extension products suitable for many fields such as building decoration: exterior wall Insulation decoration system, partition wall (fire prevention, sound insulation, etc.) system, ceiling system, floor system, wall material (plate) lining system and billboard, pipe cladding, furniture partition and other fields.

Applications:

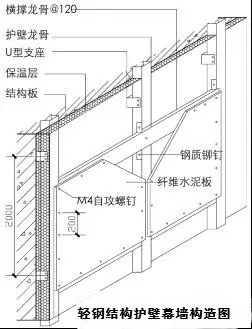

(1) Application of light steel keel partition system

Jiaheng Jiajun board, ultra-low density calcium silicate board, partition ceiling, anti-cracking board, is made of a variety of siliceous materials, calcareous materials, reinforced fiber materials, additives, etc. after copying and high-temperature autoclave curing The A-grade green decoration material is an environmentally friendly, safe and stable high-grade building decoration material, ultra-low density fiber reinforced calcium silicate board.

1. Introduction of partition wall application

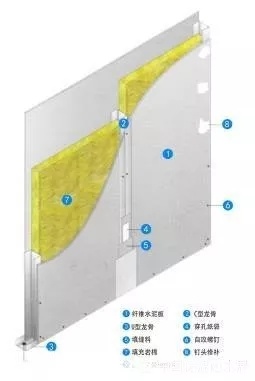

Fiber cement board light steel keel partition wall is a non-load-bearing system composed of fiber cement board, light steel keel, general accessories and other functional materials, which can meet the requirements of light weight, environmental protection, high strength, fire prevention, sound insulation and increased use space. At present, the most ideal and respected partition wall application method on the market.

2. Application Guide for Partition Wall System

According to different use parts and functions, the corresponding fiber cement board, light steel keel and wall structure should be carefully considered.

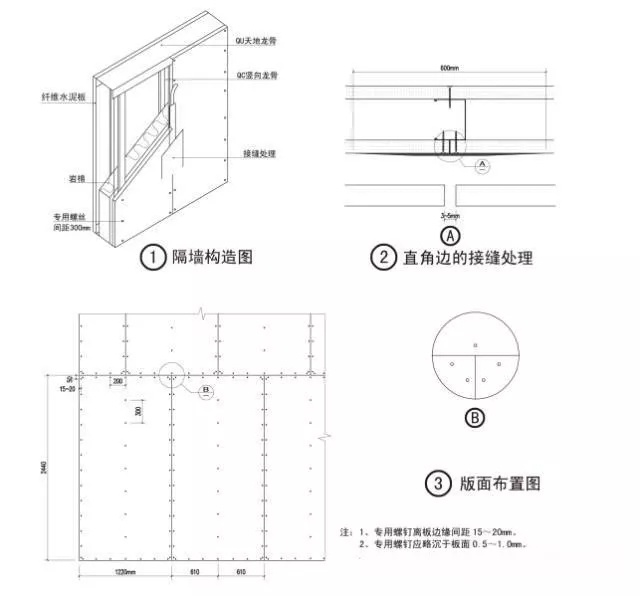

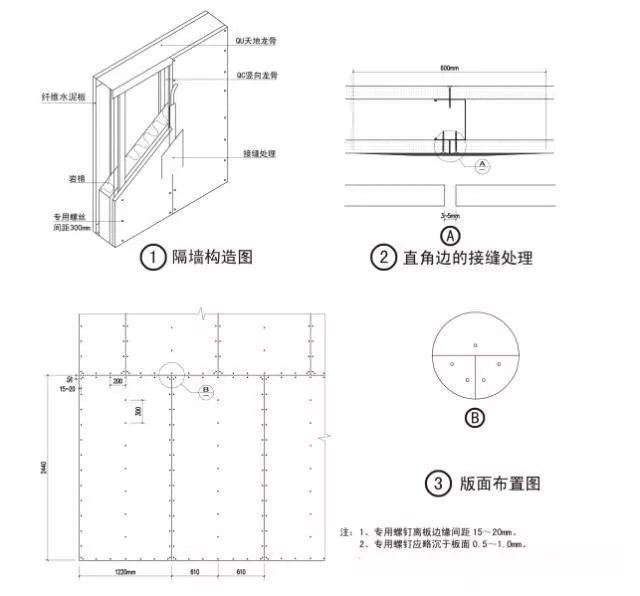

2.1 Selection of plates

When a layer of medium density fiber cement board is nailed on both sides of the ordinary building keel, the thickness of the board should be ≥8mm, and the thickness of the board should be 9mm or 12mm for the parts that are vulnerable to impact; ≥8mm. If it is used for medium and high-grade building plates, the thickness should be increased by 1-2mm accordingly.

2.2 Selection of partition keel

In the design of the partition wall system, the height, length, building type and pipelines that need to be hidden in the wall should be considered in order to select a keel with a suitable width. The limit height of the partition wall is mainly determined by the strength and stiffness of the light steel keel.

Note:

① Light steel keel must meet the requirements of GB/T 11981 "Light Steel Keel for Construction";

② The height listed in the table is the limit height when the keel spacing is 610mm. When the keel spacing is reduced, the height of the partition wall can be increased;

③ The design control height is listed in the table. When the limit height is exceeded, the transverse bracing keel shall be added. When both sides of the partition wall are double-layer boards, the control height can be relaxed by one-fifth according to the figures in the table above;

④ When the height of the partition wall is greater than or equal to 2440mm, the horizontal bracing keel shall be added and fixed with blind rivets or bolts;

⑤ When the height of the partition wall is greater than or equal to 5000mm, in order to ensure the stability of the wall, consideration should be given to adopting different keel skeleton structures (double rows, double buckles, etc.) or steel structure frames (inner hidden) to increase the limit height of the wall.

2.3 Sound insulation and fire protection structure

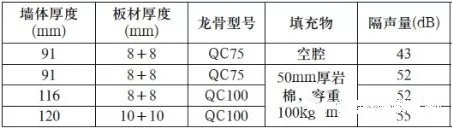

1) Sound insulation structure

The sound insulation effect of the partition wall is closely related to the structure, and the main factors are the density of the board used, the number of layers and the thickness of each layer, the width and setting method of the keel, whether it is filled with sound-absorbing materials and its quality.

★ Sound insulation wall practice

If the wall is required to have a high sound insulation capacity, a special structure can be used, but special attention should be paid to the tight seal between the wall and the surrounding structure. Common practices include:

① Filling the partition wall with sound insulation cotton can greatly improve its sound insulation effect;

② Double-layer board structure is adopted, and high-strength self-tapping screws should be used to fasten the board accordingly;

③ Use plates of different thicknesses (such as 8mm and 10mm) or two different densities on both sides of the keel to improve its sound insulation effect;

④ Use two rows of independent keels to replace the single-layer keel, so that the mutual influence between the two panels is reduced, so as to achieve the purpose of improving the sound insulation effect.

★ Sound insulation performance index

2) Fireproof structure

Fiber cement board belongs to A1 grade other material, which has excellent fire resistance and flame retardant properties. The fireproof structure of fiber cement board partition wall generally consists of fiber cement board, light steel keel and fireproof filler. Among them, the board can ensure the integrity of the structure at high temperature, the fireproof filler can prevent temperature penetration, and the keel can support.

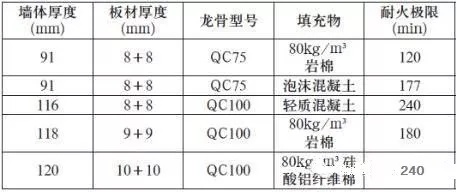

★ Fire resistance index

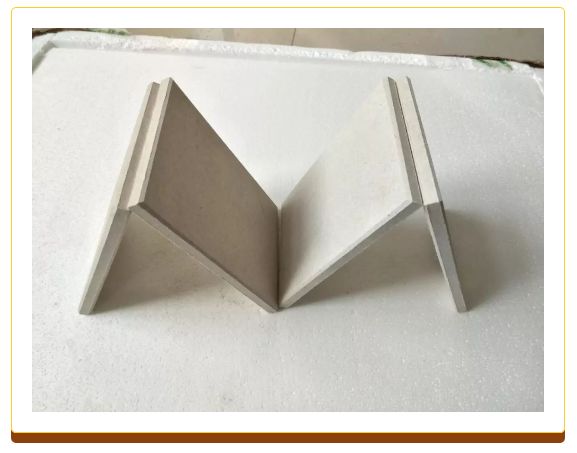

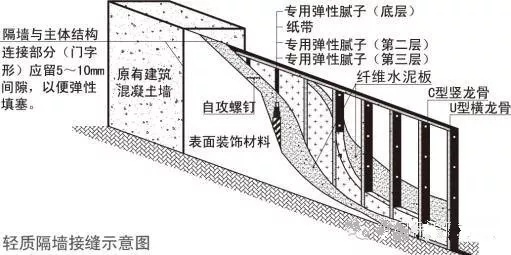

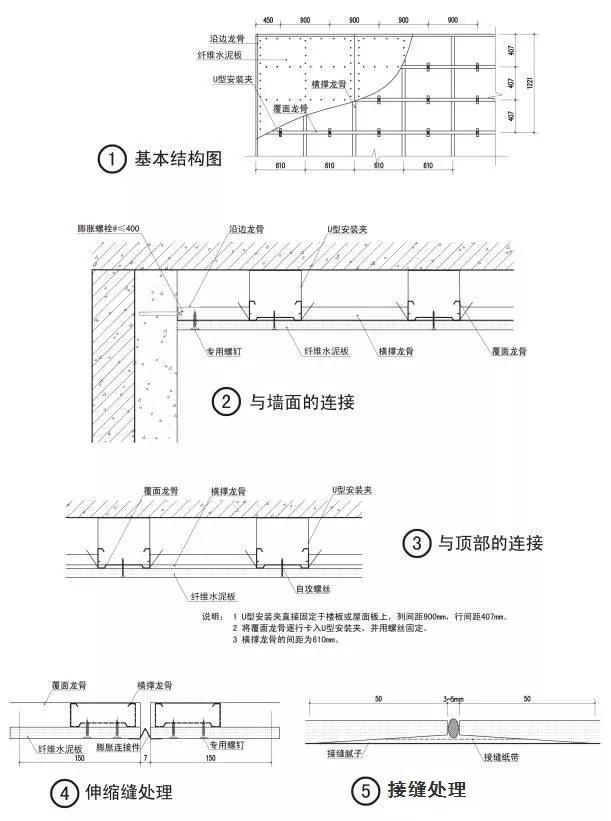

2.4 Seam treatment

Before the fiber cement board is installed and finished, it is necessary to caulk the board seams. Excellent caulking supporting materials and professional and standardized construction ensure the stability and durability of the joints of the partition wall system.

★ Right-angle edge seam (dark seam) treatment construction steps:

① In a clean container, prepare the joint material with clean water;

② At the joint, use the adjusted joint material to fill up the gap and the nail hole (anti-rust treatment) and wait for drying;

③ Cover with perforated seam tape, press it tightly, and let it dry;

④ Brush the bottom surface treatment liquid on the board surface and joints, and let it dry;

⑤ Apply the joint putty on the joint belt, scrape off the excess putty on the joint belt board, pay attention to leveling, the width of the first layer of joint treatment is 100mm;

⑥ After the first layer of joint putty is dry, apply the second layer of joint putty, and the width of the second layer of joint treatment is 200mm (the joint size of the right-angle edge plate is 300mm);

⑦ Apply the third layer after drying, pay attention to the smoothness of the surface. The width of the third layer of seam treatment is 300mm (the seam size of the right-angle edge plate is 600mm);

⑧ After the seams are completely dry, sand them with sandpaper.

★ Notes:

① The joint putty should be the water-resistant putty in JG/T 3049-1998 "Putty for Building Interior";

② The joint treatment must wait until the moisture content of the board is relatively balanced with the air humidity before construction;

③ In some places with high air humidity, the method of interfacial treatment of the board can be used to reduce the water absorption rate of the board and improve the dimensional stability of the board. For example, after sealing the board, apply WACKER silicone ( WACKER BS SMK1311) or Dow Corning water repellent (Dow Corning DC520) and other materials, and then carry out joint construction after seven days;

④ In order to prevent the bottom layer of putty from drying too fast before the seam tape is applied, the length of the bottom layer of putty should not be greater than 5m each time. construction;

⑤ In order to minimize cracking at the joints of the plates, all joint materials should be selected from materials with certain tensile strength, strength and cohesive force, and materials with elasticity and adhesion should be selected for the full batch of putty;

⑥ The wall installation process has a great influence on the joint effect, and a series of measures should be taken during installation to avoid the risk of subsequent joint failure;

⑦ The "door"-shaped gap should be left between the partition wall and the main structure, and the gap should be filled with elastic silicone

2.5 Nodes of Standard Partition Wall System

2.6 Nodes of grouting wall system

The fiber cement board lightweight grouting wall system is based on high-quality light steel keel as the frame, fiber cement board as the cladding panel, and light weight concrete slurry is poured into the partition wall cavity formed between the keel frame and the fiber cement board. The formed solid lightweight wall is a new type of wall. It is widely used in the outer walls and non-load-bearing inner partition walls of buildings with high requirements on fire protection and impact resistance. Finishing needs to be done 28 days after grouting is completed.

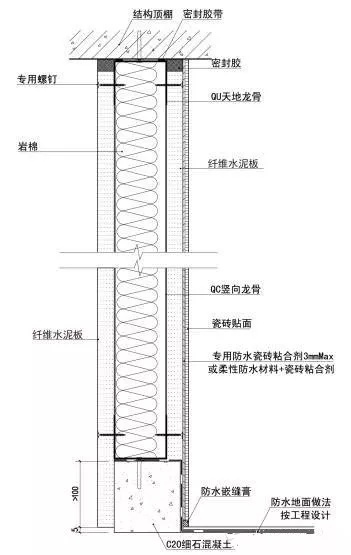

2.7 Sanitary Partition Wall System

The bathroom is one of the most humid spaces in the building and must be waterproof, leak-proof, odor-proof and clean. Fiber cement board has good waterproof, moisture-proof, anti-corrosion and moth-proof properties, which can effectively avoid the occurrence of such problems. The toilet partition wall is similar to the standard partition wall or grouting partition wall, the difference is that a concrete water-stop wall pad is required at the bottom. Its surface can be processed in various ways, such as applying waterproof paint, pasting marble, ceramic tile, aluminum-plastic panel, cultural stone, etc.

(2) Application of ceiling system

Jiaheng Jiajun board, ultra-low density calcium silicate board, partition ceiling, anti-cracking board, is made of a variety of siliceous materials, calcareous materials, reinforced fiber materials, additives, etc. after copying and high-temperature autoclave curing The A-grade green decoration material is an environmentally friendly, safe and stable high-grade building decoration material, ultra-low density fiber reinforced calcium silicate board.

1. Introduction of ceiling application

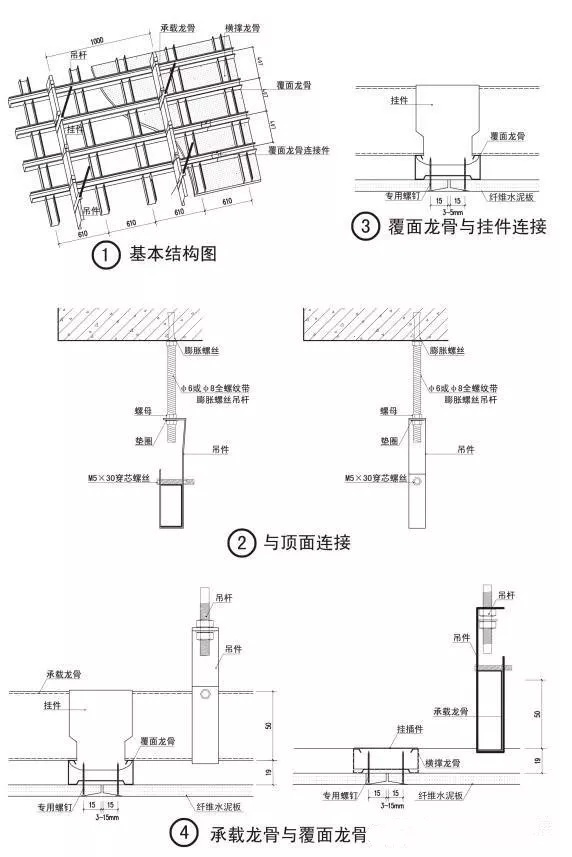

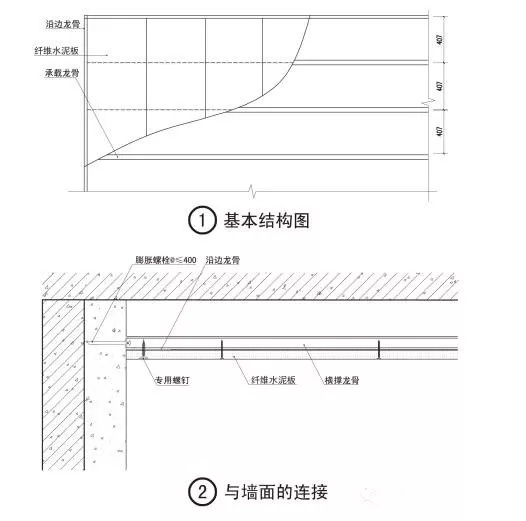

Fiber cement board can also be used for ceiling system, and the base plate is mostly used for dark keel ceiling system. It refers to the ceiling system formed by fixing fiber cement board on the light steel keel of the ceiling, and the keel frame is not exposed.

The main system components of this application are DL edge keel, DU main keel, DC auxiliary keel, DC cross-bracing keel and accessories. The dark keel ceiling system can be divided into two types according to the different loads: the ceiling for people and the ceiling for people without access.

1) Venerable ceiling: Mainly divided into 60/60, 60/50, 50/50 (main/auxiliary keel width).

System Requirements:

● Ceiling load: the load per square meter is not less than 800N

● Diameter of boom: not less than 8mm

● Thickness of main keel: not less than 1.2mm

2) Non-passenger suspended ceiling: Mainly divided into 50/50, 38/50 (main/auxiliary keel width).

System Requirements:

● Ceiling load: 500~800N per square meter

● Diameter of boom: 6~8mm

● Thickness of main keel: 0.8~1.0mm

2. System Application Guide

2.1 Selection of plates

The thickness of the ceiling board can generally be selected from 4mm, 5mm, 6mm, and the thickness of the large-size board can be selected from 8 to 12mm. The board can also be punched and used as a sound-absorbing ceiling.

2.2 The installation and nodes of the dark keel ceiling system (accessible/non-accessible ceiling)

2.3 Installation and nodes of dark keel ceiling system (veneer ceiling)

2.4 Installation and nodes of dark keel ceiling system (self-supporting ceiling)

(3) Application of floor system

Jiaheng Jiabao board, fiber cement board floor board, adopts pure Portland cement, selected quartz sand, plant fiber, and selected mineral filler. Among them, cement is the main component, which acts as a hydraulic binder; the interaction between the fiber component and the cement matrix generates a stable matrix structure; after the mineral filler is ingested and cured by high temperature autoclave, tobermorite-like molecules are formed. The structure and physical properties are extremely stable.

1. Introduction to floor application

The fiber cement board thick plate (generally 20-30mm) and the supporting frame can form a floor system, the old building can be added to the floor and the floor in the LOFT (loft) building, etc. It has the advantages of fireproof and moisture-proof, light weight and short construction period. After installation, the surface can be pasted with tiles, wood floors, carpets, and floor paints.

2. System Application Guide

2.1 Selection of plates

The thickness of the floor slab is generally 20-30mm high-density thick slab (specifically according to the load-bearing requirements).

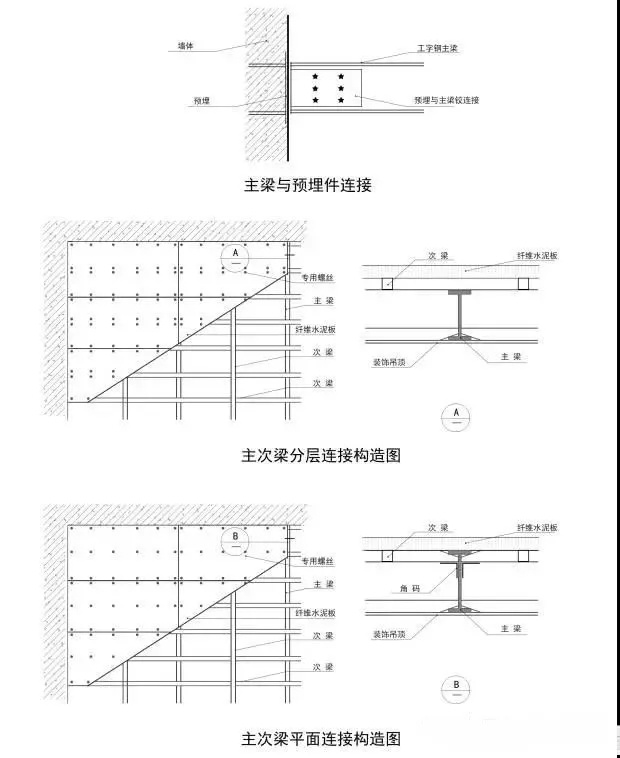

2.2 Selection of support frame

The specifications of the main beam should be calculated and designed by the engineer according to the span, and at the same time, the bearing strength of the original structure wall should be considered comprehensively, and the hexagonal drill tail screw should be fixed.

2.3 Floor system installation and nodes

Note:

① When the storey height is sufficient, the main beam and the secondary beam can be connected by the top, and the plane connection can be used when the height is small;

② The weight-bearing point of the hanging heavy object should fall on the main beam, and the basic structure should not be greater than 40kg/㎡;

③ Generally, the distance between the main beams is 2440mm, the distance between the secondary beams parallel to the main beam is 1220mm, and the distance between the secondary beams intersecting with the main beam is 610mm.

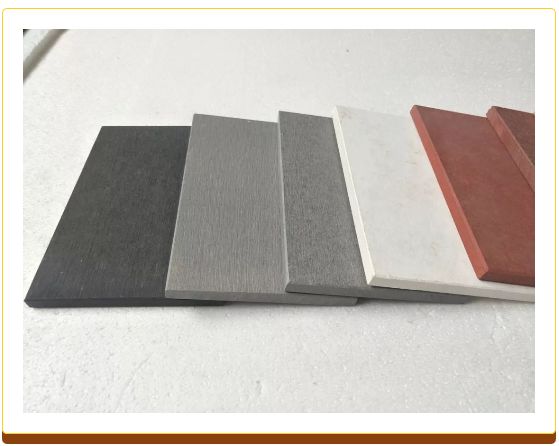

(4) Application of external wall system

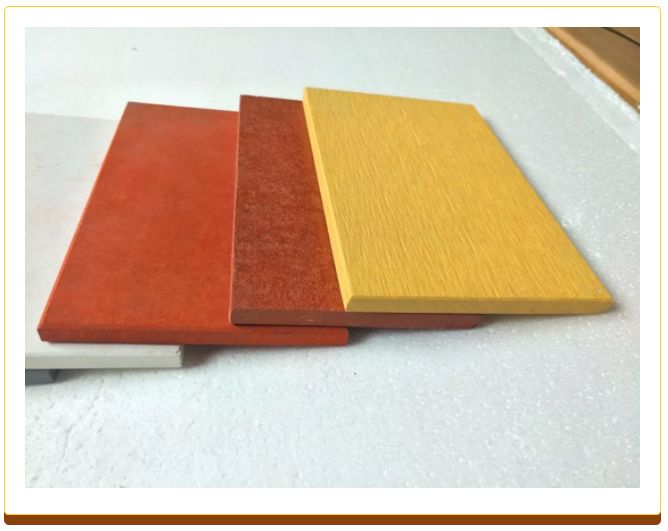

Jiaheng Jialai board, fiber cement board decorative surface material, uses natural raw materials, including Portland cement, selected quartz sand, plant fibers, natural mineral pigments and other real materials, after high temperature autoclave curing.

1. Introduction of exterior wall application

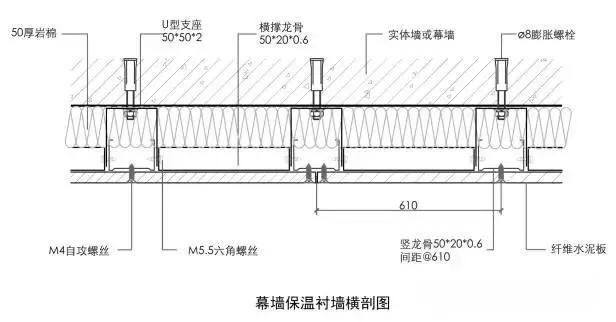

The fiber cement board exterior wall system is composed of fiber cement board, keel frame, support, etc., and is installed on the building structure through anchors. The system can be used as building curtain wall, curtain wall lining, or decoration (finishing), external thermal insulation (filling in thermal insulation materials), etc.

2. System Application Guide

2.1 Selection of plates

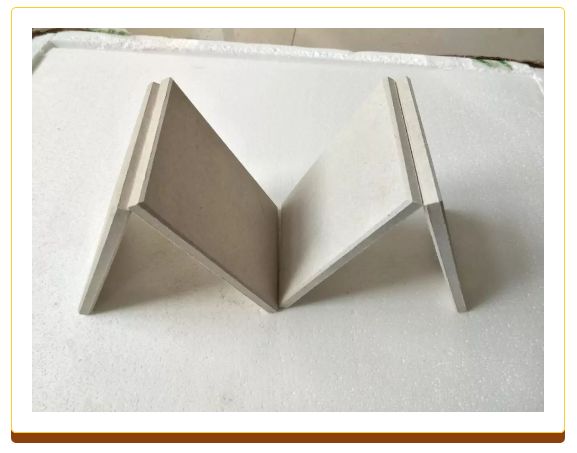

Generally, high-density fiber cement board (and its post-processing veneer) can be selected.

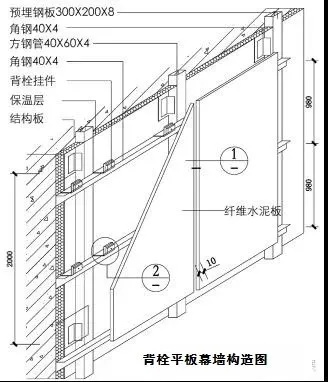

2.2 The choice of connection method

The connection method used by the system is selected according to the type of plate and installation needs. The thin plate (about 6mm) can be directly pasted on the lining wall with AB glue; 5x38mm) or stainless steel rivets (M4.8x25mm, rivet cap ø16mm) to fix; thick plates (above 12mm) are generally fixed with ø6 back bolt members, the thickness of the plate after the back bolt hole should be more than 30% of the total thickness of the whole plate, The specific calculation is based on professional basis.

2.3 Curtain wall thermal insulation lining wall, inner lining wall and glass curtain wall fire skirt

2.4 Retaining curtain wall

2.5 Back-bolt slab curtain wall

(5) Finishing treatment

Jiaheng Jialai board, fiber cement board decorative surface material, uses natural raw materials, including Portland cement, selected quartz sand, plant fibers, natural mineral pigments and other real materials, after high temperature autoclave curing.

1. Paint decoration

The properties of the selected coatings should be suitable for reinforced fiber cement products, such as acrylic or epoxy series coatings. When the smoothness and finish of the layout are required to be high, the board can be fully plastered before the finishing, then sanded with a sander, and then treated with a decorative surface.

2. Paste wallpaper or wall covering

This is a relatively simple and practical way of interior wall or ceiling decoration. Paste materials are mainly white latex, polyethylene and other water-soluble viscose.

3. Veneer panel

A simple and convenient way to decorate. The sticking materials can be white latex, all-purpose glue such as Immediate, high-grade glass glue, structural parts and marble glue, etc., to directly stick veneer, fireproof board, PVC sheet, etc. to the panel.

4. Tile

It is recommended to use special tile adhesive to ensure the firmness of the tiles.

5. Paste marble

Paste with marble glue or high-quality strong anti-sagging adhesive. It is generally recommended to paste marble wall skirts, and the thickness should not be greater than 20mm.

(6) Matters needing attention

In order to ensure the quality and use effect of fiber cement board, it is especially necessary to pay attention to the following matters during handling, storage and use and processing:

1. Handling

The entire fiber cement board has a large width, so please do not carry it alone to prevent the board from being over-bent and causing breakage. At the same time, pay attention to the protection of the edges and corners to avoid damage to the board due to collision.

2. Storage

Although the board is light and high-strength, if it accumulates excessively during the storage process, it may cause the bottom board to be deformed or damaged due to excessive pressure. It is recommended that the stacking height of a single stack is less than 0.8m, and the total stacking height is less than 2.4m to ensure the integrity of the board.

3. Processing

★ The plate is easy to process: it can be nailed, sawed, planed and drilled;

★ Sheets should be cut in an open outdoor environment or in a well-ventilated environment;

★ Please use electric cutting equipment with suction device;

★ Cutting operators should wear masks;

★ Dust left by cutting should be cleaned up in time to avoid environmental pollution caused by flying;

★ Please operate in accordance with the engineering safety requirements during the installation process to avoid danger.

Related news

2021-09-15

2021-09-15

2021-09-15

Hotline: 008613318898449

Address: No.23,Tanbu Industry Zone,Tanbu Town,Huadu District,Guangzhou,Guangdong,China.

Email: sanly@jiahengboard.com

We will give you feedback in time

Guangzhou Jiaheng Board Industry Co.,Ltd.

Mobile/Wechat: 008613318898449

Tel:020-86843698

E-mail:sanly@jiahengboard.com

Address: No.23,Tanbu Industry Zone,Tanbu Town,Huadu District,Guangzhou,Guangdong,China.

Guangzhou Jiaheng Board Industry Co.,Ltd. seo

粤ICP备14070170号 Power By:www.300.cn

[ WeChat ]

[ Mobile ]